Welcome to Zhengzhou Xinli Wear-Resistant Material Co. Ltd.

Welcome to Zhengzhou Xinli Wear-Resistant Material Co. Ltd.

The research team of Wai Sze YIP and Suet TO from the Hong Kong Polytechnic University published a review paper entitled “3D printing for ultra-precision machining: current status, opportunities, and future perspectives” in the August 2024 issue of Frontiers of Mechanical Engineering. The article outlines the current status of ultra-precision machining (UPM) technology for 3D printing, analyzes the benefits of combining UPM with 3D printing, and further discusses the future prospects of integrating these two advanced manufacturing technologies into potential industries.

1. Research Background

UPM and 3D printing are two emerging technologies with great potential. UPM follows the principle of subtractive manufacturing, and 3D printing is based on the principles of rapid prototyping and additive manufacturing. However, although 3D printing technology has certain advantages, it still has shortcomings in terms of accuracy and surface quality. Therefore, it is proposed to combine 3D printing and UPM technology. This paper describes the salient features and sources of UPM and 3D printing technologies. The advantages and applications of the combination of the two technologies are elaborated in detail, and the forward-looking development of this combination of technologies is evaluated. The purpose of the study is to use the capabilities of advanced manufacturing and machining technologies to promote industry progress and bridge the existing gaps in related research fields.

2. Main research content

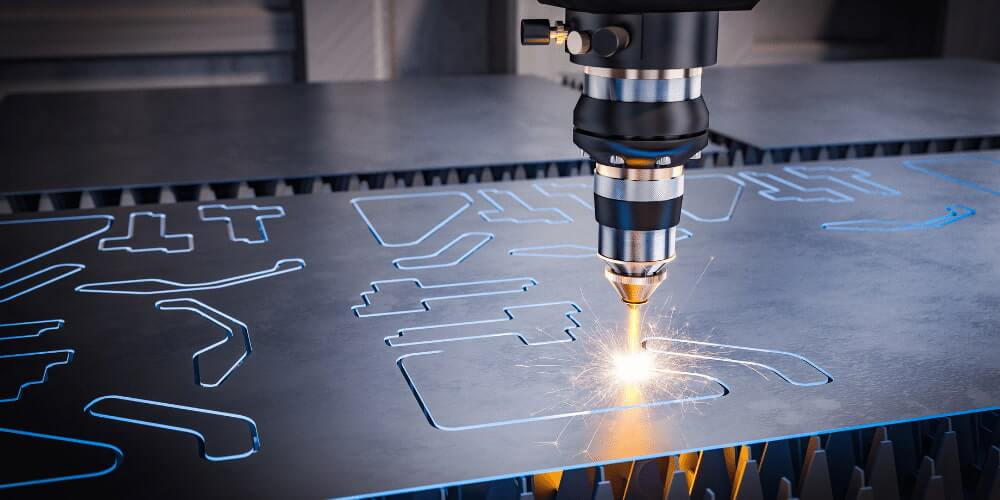

Based on the principle of subtractive manufacturing, UPM achieves nano-level processing accuracy through milling, grinding and polishing, and is widely used in laser, optics, electronics and other fields, but there are problems with low material removal rate and sustainability. The tools used, such as diamond tools, are crucial to the processing quality, and the surface generation mechanism is affected by many factors. Simulation modeling and artificial intelligence technology can assist in optimizing the processing process.

3D printing is based on the principle of additive manufacturing and can manufacture complex structural parts. It has the advantages of less material waste and high cost-effectiveness, but there are challenges in terms of accuracy, surface quality and materials. This technology is divided into extrusion-based and laser-based additive manufacturing types. It is widely used in aerospace, biomedicine and other fields, and can also be used for traditional processing, such as manufacturing molds and complex structural parts.

3D printing has limitations in industrial applications, such as printing material defects, poor surface quality, and dimensional accuracy affected by many factors. It also faces challenges in the commercialization of micro-scale manufacturing. Different 3D printing technologies have their own advantages and disadvantages, such as the high cost of selective laser sintering (SLS) equipment and materials, and obvious printing marks in fused deposition modeling (FDM).

3D printing technology can manufacture cutting tools of various materials, such as carbide, ceramic and diamond tools, etc. It has unique structural and performance advantages, can improve processing performance, and has market potential in UPM. UPM of 3D printed parts can solve problems such as surface quality, dimensional accuracy and mechanical properties. It has important applications in molds, optics, machinery and microelectronics, and can improve product quality and performance. UPM post-processing can improve the surface finish, dimensional accuracy and material properties of 3D printed parts. In the biomedical field, the combination of the two is crucial to realize the potential for clinical applications.