Abrasive is the main body of material removal in Abrasive Water Jet Polishing technology. Its shape, size, type and other parameters have a direct impact on the processing efficiency and the surface quality of the processed workpiece. The types of abrasives commonly used at present are:

SiC,

Al2O3, CeO2, garnet, etc. Generally speaking, the greater the hardness of the abrasive grains, the greater the material removal rate and surface roughness can be improved.

In addition, there are also the following factors that will affect the polishing quality:

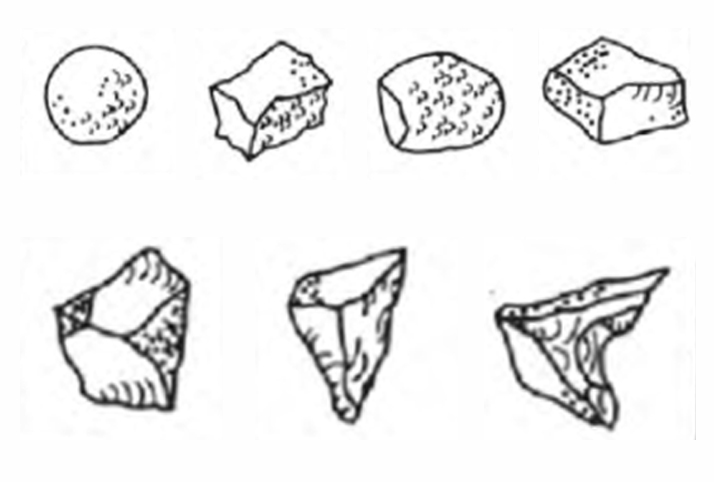

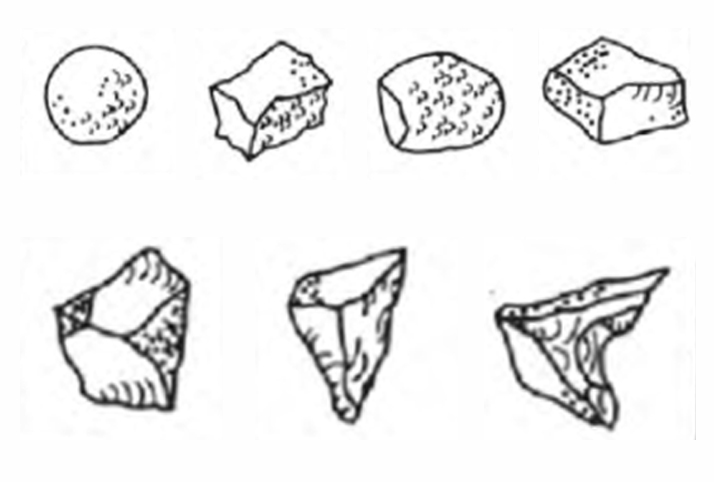

① Roundness: The impact of abrasive particle roundness on processing. The results show that the greater the abrasive roundness, the greater the exit speed, the higher the material removal rate, and the smaller the nozzle wear.

② Uniformity: The impact of particle size uniformity on jet removal characteristics. The results show that the impact removal rate distribution of particles of different particle sizes is similar, but the impact removal rate decreases with the increase of particle size.

③Particle size: The impact of abrasive particle size on material removal. When increasing the abrasive size, the cross-section of the removed material changes from a W shape to a U shape. Through experimental analysis, it is concluded that the collision between particles is the main cause of material removal, and nano-scale Particle-polished surfaces are removed atom-by-atom.