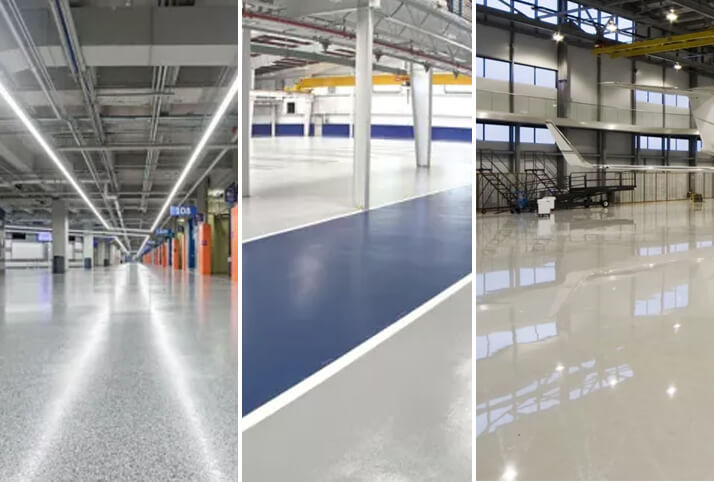

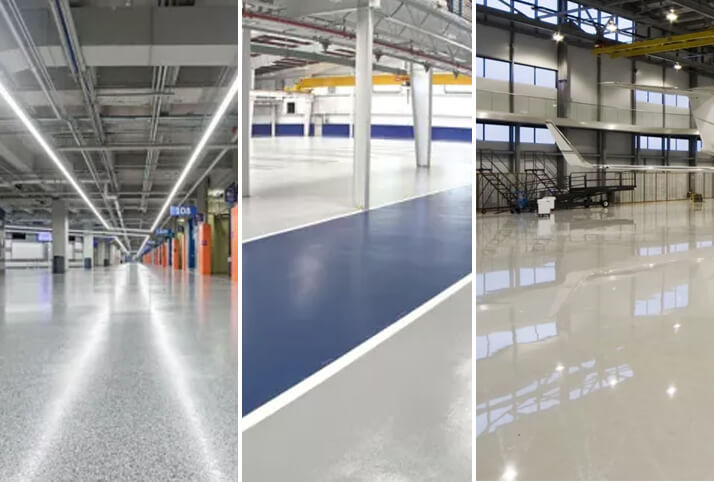

In response to the increasing demand for durable flooring in various applications such as airports, docks, and workshops, the use of wear-resistant floors has become essential. These floors, known for their exceptional wear and impact resistance, require meticulous attention during construction, particularly concerning the choice of aggregates. White fused alumina, valued for its high purity and hardness comparable to that of diamond, has gained popularity as a favored aggregate for wear-resistant flooring projects. Here are crucial precautions to consider when utilizing

white fused alumina for creating wear-resistant floors:

-

- 1.Concrete Setting Time Experimentation:

Prior to commencing the floor construction, it’s imperative to conduct concrete setting time experiments. White fused alumina can only be successfully applied to the surface when the concrete’s setting time aligns with the construction schedule. If the setting time is too rapid, it may hinder proper adhesion, while excessively slow setting can result in undesirable surface bubbling due to extended cement slurry exposure.

-

- 2.Formulate an Optimal Concrete Construction Process:

Developing a well-structured concrete construction process is pivotal in ensuring synchronization between concrete placement and wear-resistant surface application. A streamlined approach minimizes construction time while maintaining quality standards, ultimately enhancing the efficiency of the entire project.

-

- 3.Employ Experienced Construction Personnel:

Opting for skilled and experienced construction personnel, despite potentially higher costs, guarantees a higher level of precision and craftsmanship. Professionals who possess expertise in wear-resistant flooring are more adept at maintaining consistent floor levels and executing surface constructions with unparalleled finesse. The utilization of experienced personnel safeguards against premature floor deterioration and maximizes its longevity.

Incorporating

white fused alumina into wear-resistant flooring projects offers numerous advantages, including robust wear and impact resistance and resilience against acid and alkali corrosion. By adhering to the precautions mentioned above, construction teams can optimize the utilization of white fused alumina and ensure the successful implementation of wear-resistant floors in diverse industrial and commercial settings.