Application of zirconium oxide in ceramic cutting tools

Zirconia

Zirconia is widely used in ceramic tool manufacturing due to its high hardness, high strength and wear resistance. Below we will introduce the application of zirconia in ceramic cutting tools in detail.

1.

Improvement of tool hardness

Zirconia’s very high hardness can significantly improve the hardness of ceramic tools. By compounding zirconium oxide with other ceramic materials, ceramic tools with high hardness can be prepared to improve their wear resistance and cutting performance.

2.

Enhancement of tool strength

Zirconia has good strength and toughness, which can enhance the strength and toughness of ceramic tools. By controlling the content and distribution of

zirconium oxide, the mechanical properties of ceramic tools can be optimised to improve their fracture resistance and impact resistance.

3.

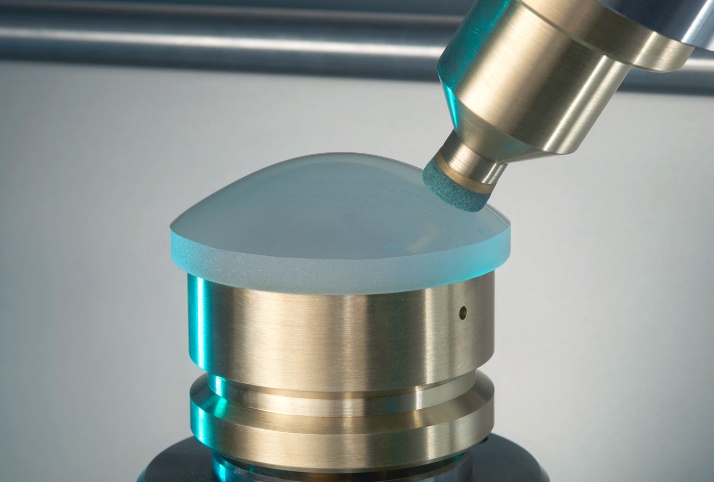

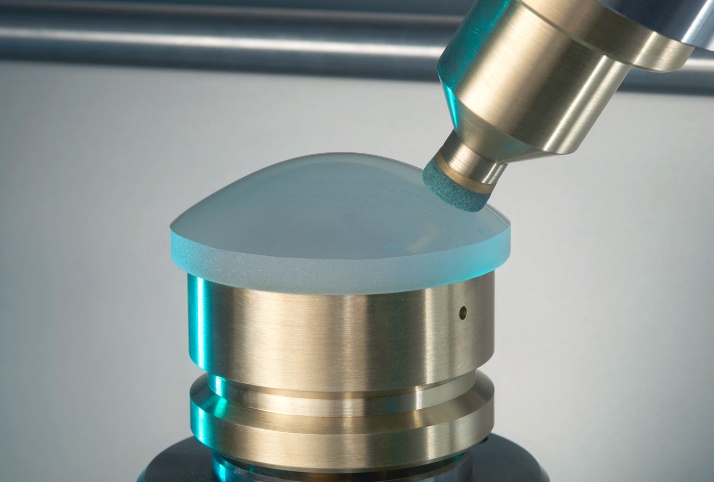

Improvement of tool machining performance

Zirconia has good machinability, and can be used to prepare dense, uniform ceramic tools by hot pressing, hot isostatic pressing and other processes. At the same time, the addition of

zirconium oxide can also improve the sintering performance and moulding performance of ceramic tools, and improve their machining accuracy and surface quality.