Because of its unique crystal shape and flaky structure,

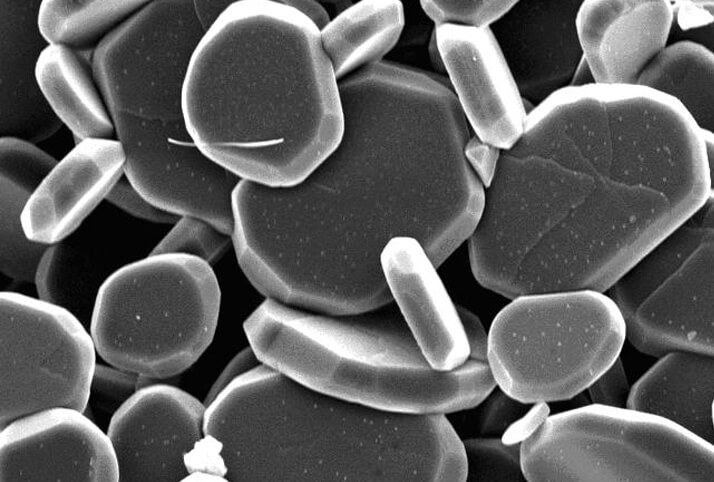

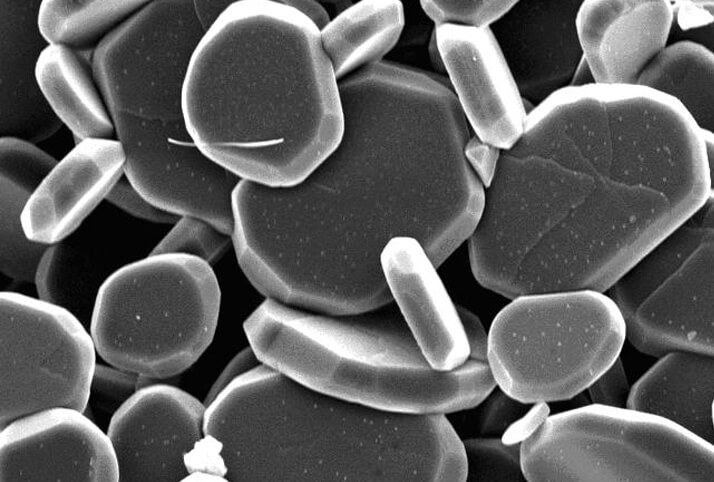

Platelet Alumina belongs to α-Al2O3, which has a significantly larger aspect ratio and scaly structure. At present, the thickness of platelet alumina grains is generally between 100-500 nm, and the radial dimension is generally 5-50 μm. Well-developed crystal particles show a regular hexagonal morphology.

Application and properties of platelet alumina:

- 1.Polishing fluid abrasive

For the processing and grinding industry, whether it is the grinding and polishing of materials or the fine grinding of electronic products, micro-powder abrasives are inseparable. Alumina also known as corundum, Mohs hardness of 9 and has great hardness, making it very suitable for grinding materials. Compared with the conventional nano-alumina, the flat and smooth surface of the platelet alumina is not easy to be scratched by the objects to be ground (such as semiconductor silicon wafers, smart phone casings, etc.), and the qualified rate of products can be improved accordingly. 10% to 15%. Therefore, platelet alumina has become a new favorite in the high-precision microelectronics industry, gem processing industry and cermet industry. platelet alumina can be used to polish the metal casing of mobile phones.

- 2.Cosmetics

Platelet alumina has small particle size and thickness distribution and large diameter-to-thickness ratio. It has stable chemical properties, almost colorless and smooth surface. It has good dispersibility in water. Most importantly, this powder is It is non-toxic and tasteless, so it is also widely used in the field of cosmetics. As an additive that can improve the thermal conductivity of cosmetics, platelet alumina can not only make cosmetics show high gloss and bright color experience, but also have a good comfort on the skin surface. It has excellent spreadability and adhesion properties, and can effectively prevent powder makeup from shedding caused by oil secretion or skin sweating.

- 3.Pearlescent Pigment

At present, the most used pearlescent pigments are usually made of natural mica flakes. However, natural mica flakes often contain colored impurity ions, which are difficult to separate, and the excessively thick edges will cause the pearlescent pigment to scatter easily, which will adversely affect its visual effect.

Synthesized platelet alumina powder with design freedom and physicochemical properties that natural mica cannot obtain. During the synthesis process, the introduction of impurities can be eliminated or controlled, while the product has a narrow particle size and thickness distribution, a large aspect ratio, almost completely colorless and smooth and flat surface, and this alumina has good performance in water. dispersion. Therefore, it is an ideal substrate for high-quality pearlescent pigments.

Platelet alumina is used as the base material of pearlescent pigments. Plate-shaped alumina is used as the matrix, and one or more layers of metal oxides with high refractive index (such as titanium dioxide, iron oxide, etc.) are coated on its surface to prepare Excellent pearlescent pigments. This pearlescent pigment can not only exert the advantages of mica-titanium pearlescent pigments, but also make up for its deficiencies, fully embodying various properties of pearlescent pigments. Moreover, compared with mica titanium pearlescent pigments, it can achieve the same effect with less coloring amount.

- 4.Functional coating

The platelet alumina with superior performance has no agglomeration phenomenon, and has good adhesion, and is easy to combine with other functional micropowders to prepare various promising new functional coatings. For example, the functional coating used for stealth aircraft can absorb radio waves to prevent being searched by radar; in addition, the alumina coating also blocks ultraviolet rays and performs photocatalysis and other functions, so it also has a good application prospect in solar panels. platelet alumina is used in solar panels.

- 5.Used as a toughening agent

Adding

platelet alumina as a second phase toughening agent to ceramics can increase crack deflection and bridging, and has a significant effect on improving the fracture toughness of ceramics. Using the method of introducing platelet alumina seeds, Al2O3 ceramics with anisotropically grown grains with a fracture strength of 600 MPa and a fracture toughness of 7.9 MPa·m1/2 can be prepared under the condition of hot-pressing sintering. Flake alumina is used to toughen structural ceramics. In addition to the introduction of lamellar crystals into alumina ceramics, the addition of tabular alumina in the preparation of other ceramics can also improve the properties of the material.

- 6.Inorganic fillers

One of the earliest applications of

platelet alumina as a filler, it was successfully used as a filler for polymers to enhance their thermal conductivity. The thermal conductivity of alumina is much higher than that of organic polymers. Adding a certain amount of flat alumina to the polymer can form an alumina network. The network can dissipate most of the heat, so the life of electronic components made of this polymer-ceramic composite can be greatly improved. the better platelet alumina is used as a polymer filler to improve heat dissipation of electronic components.