Alumina is definitely one of the most widely used and widely used varieties. You can see it everywhere. To achieve this, the excellent performance of alumina itself and the relatively low manufacturing cost are the main contributors.

Here to introduce is also a very important application of

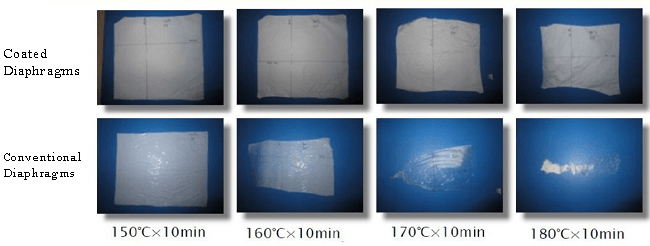

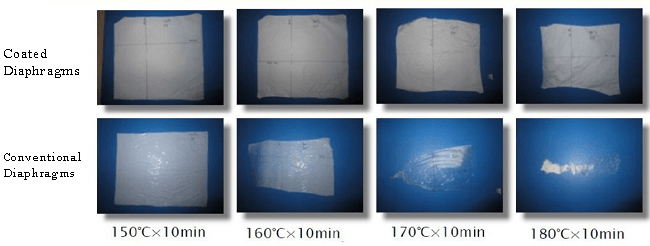

alumina powder, that is, lithium battery diaphragm coating. Diaphragm as one of the important parts of lithium-ion battery, can avoid positive and negative contact and promote lithium ion shuttle between the electrodes, determining the performance and safety of the battery. The traditional polyolefin diaphragm has a low melting point and poor stability at high temperatures, which seriously affects the safety of the battery, the current inorganic ultrafine powder coating or composite modified polymer is one of the effective ways to improve the thermal stability of the diaphragm.

In order to improve the high-temperature performance of lithium battery separators, aluminum oxide particles can be coated on the surface of polyolefin separators with the assistance of polymer binders. Alumina mainly plays the advantage of high temperature resistance, and can maintain the integrity of the diaphragm even at high temperatures of 180°C. In addition, it also neutralizes free HF in the electrolyte to improve the acid resistance and safety performance of the battery; it can form a solid solution in the lithium battery to improve the rate capability and cycle performance, has good wettability, and has certain Liquid absorption and liquid retention capabilities, etc.

In terms of application, alumina-coated lithium battery separators are favored by many industry leaders. Companies such as Sanyo, LG, and Maxell have all adopted alumina-coated separators to improve battery safety performance.

Zhengzhou Xinli Wear-Resistant Materials Co., Ltd. can provide

alumina powder for various purposes. Welcome to place an order for consultation.

In order to improve the high-temperature performance of lithium battery separators, aluminum oxide particles can be coated on the surface of polyolefin separators with the assistance of polymer binders. Alumina mainly plays the advantage of high temperature resistance, and can maintain the integrity of the diaphragm even at high temperatures of 180°C. In addition, it also neutralizes free HF in the electrolyte to improve the acid resistance and safety performance of the battery; it can form a solid solution in the lithium battery to improve the rate capability and cycle performance, has good wettability, and has certain Liquid absorption and liquid retention capabilities, etc.

In order to improve the high-temperature performance of lithium battery separators, aluminum oxide particles can be coated on the surface of polyolefin separators with the assistance of polymer binders. Alumina mainly plays the advantage of high temperature resistance, and can maintain the integrity of the diaphragm even at high temperatures of 180°C. In addition, it also neutralizes free HF in the electrolyte to improve the acid resistance and safety performance of the battery; it can form a solid solution in the lithium battery to improve the rate capability and cycle performance, has good wettability, and has certain Liquid absorption and liquid retention capabilities, etc.